CMM Part Inspection

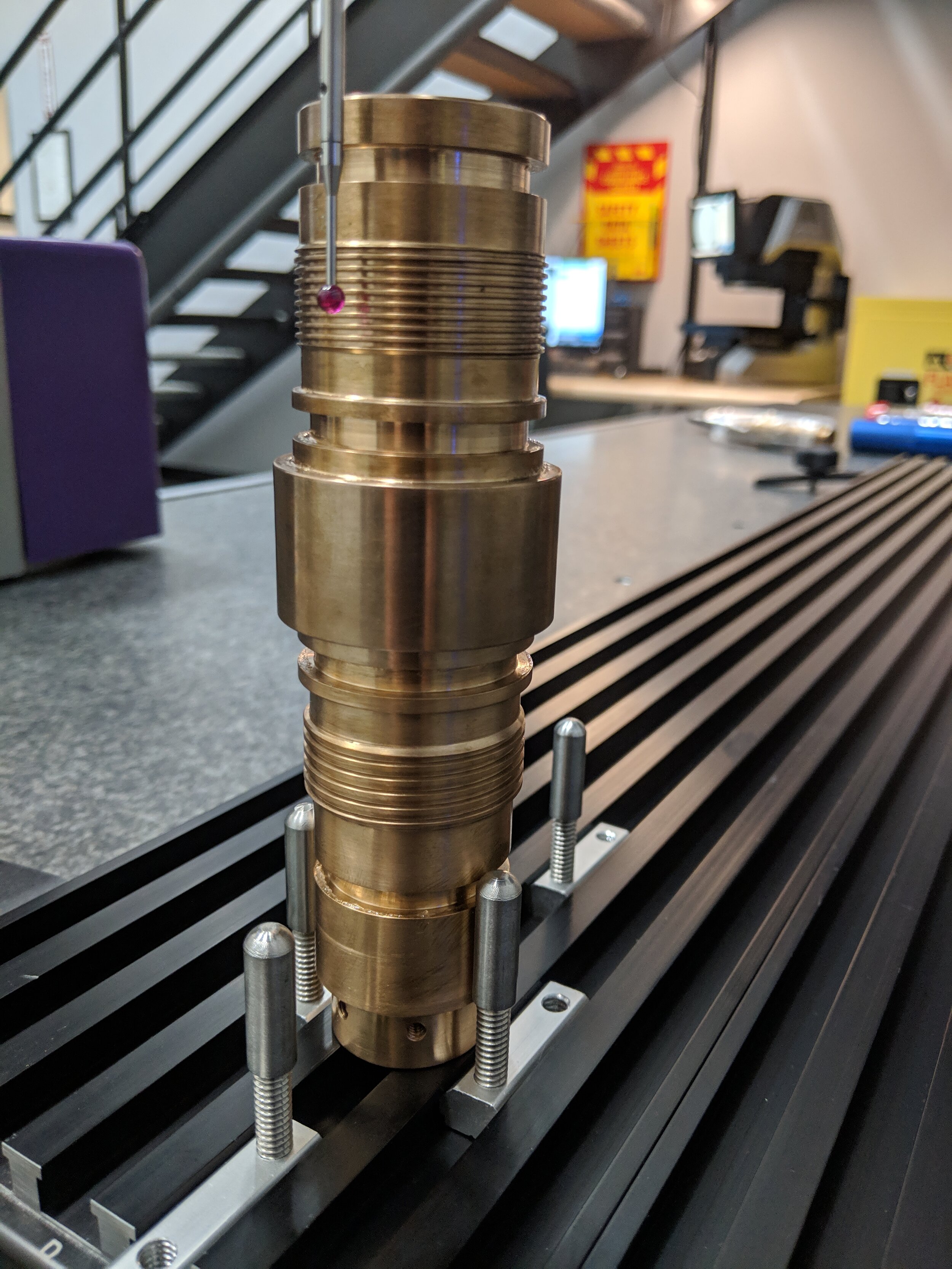

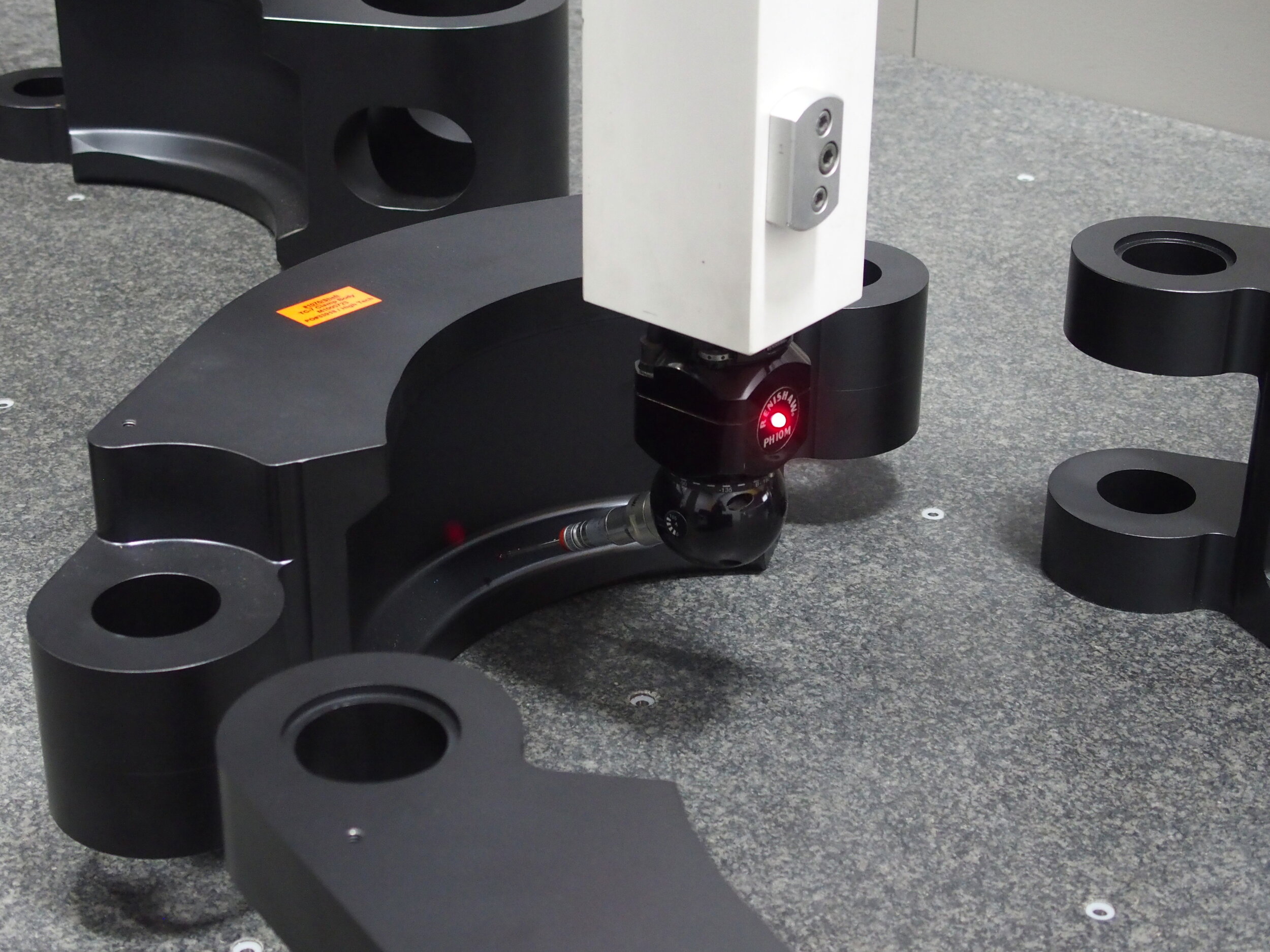

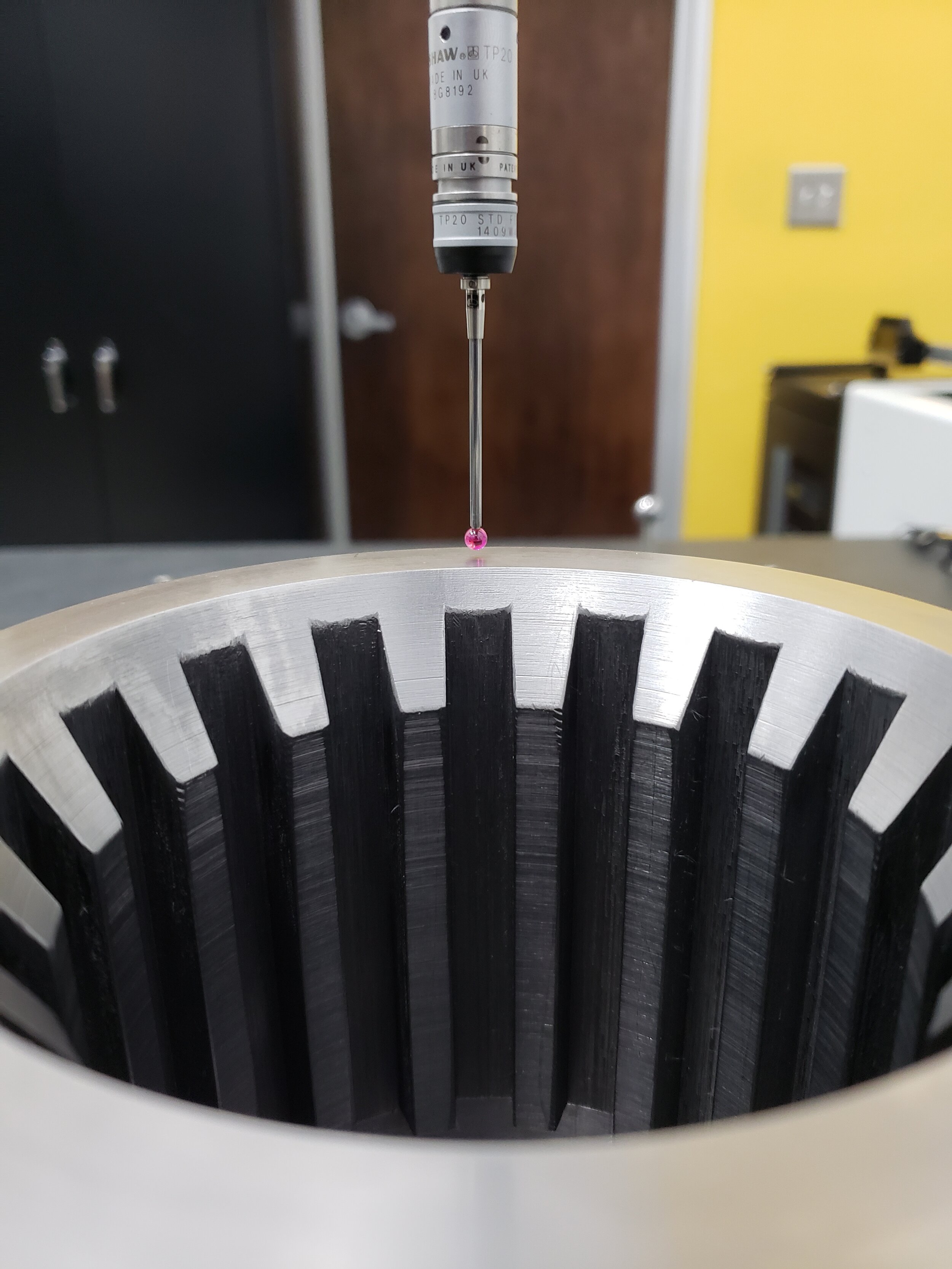

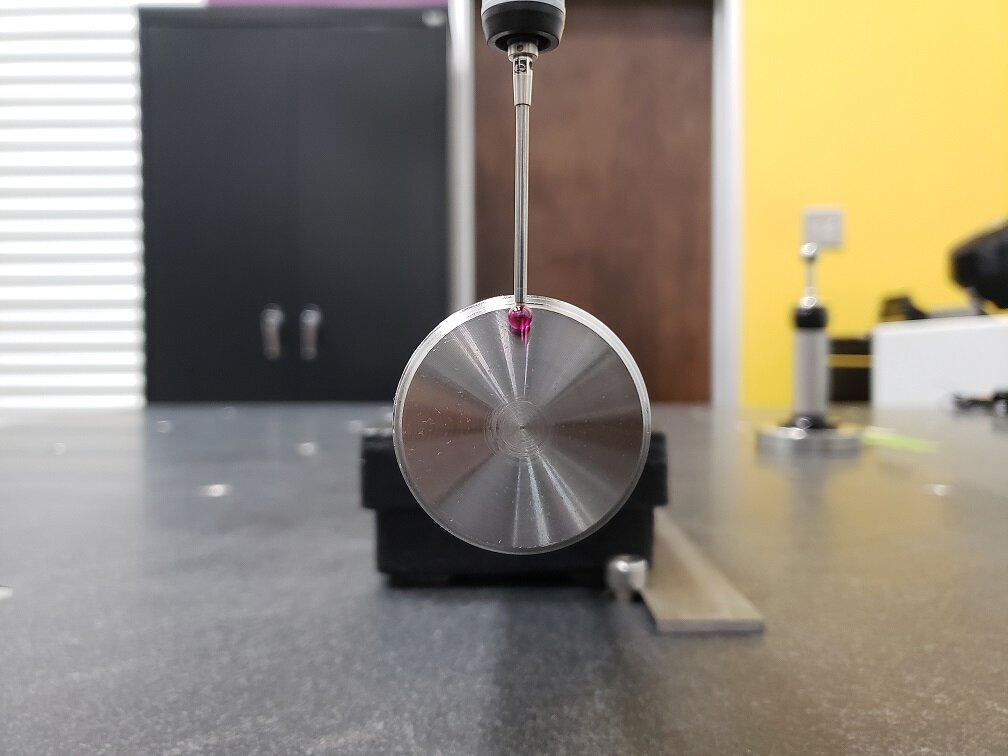

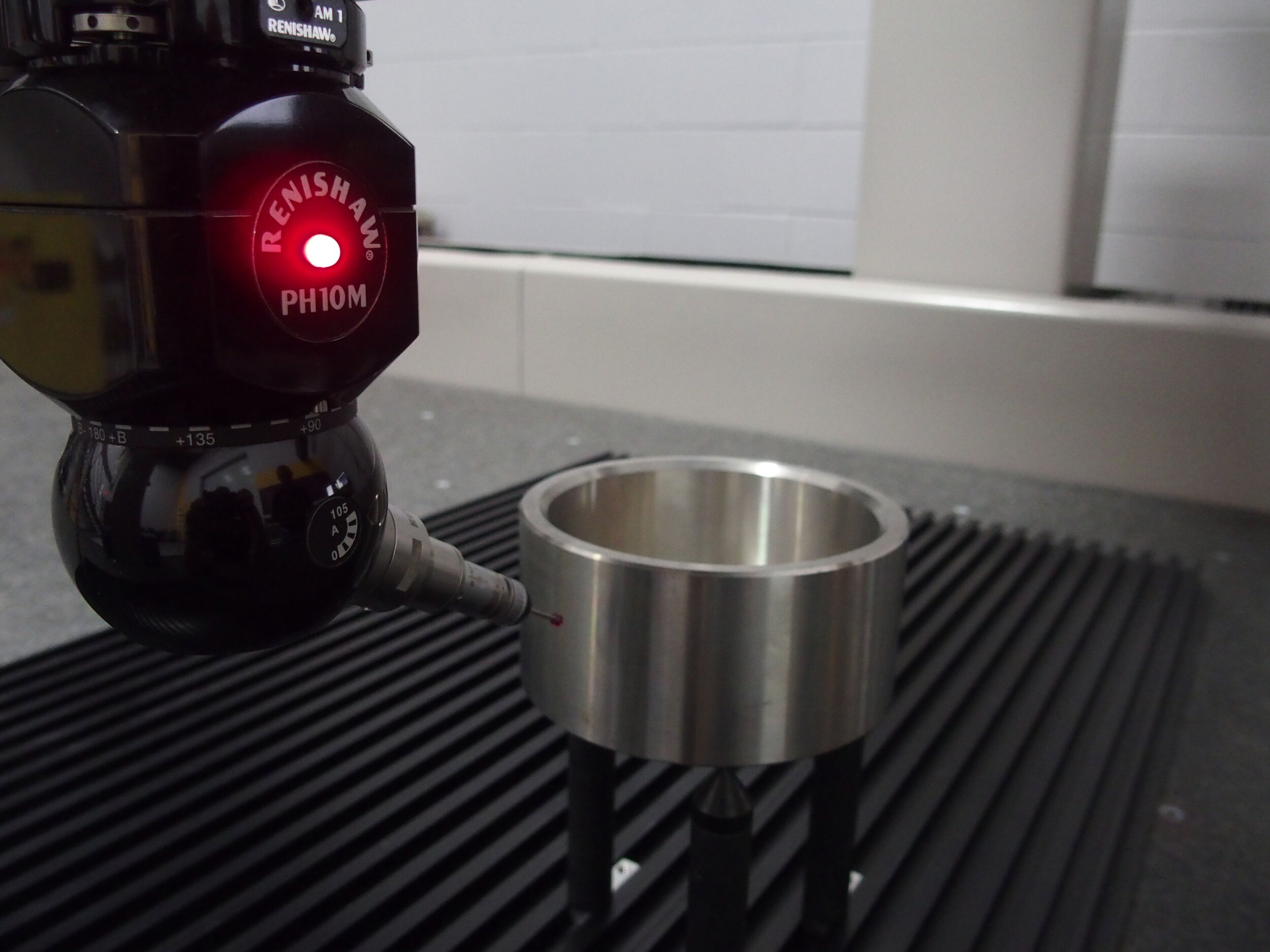

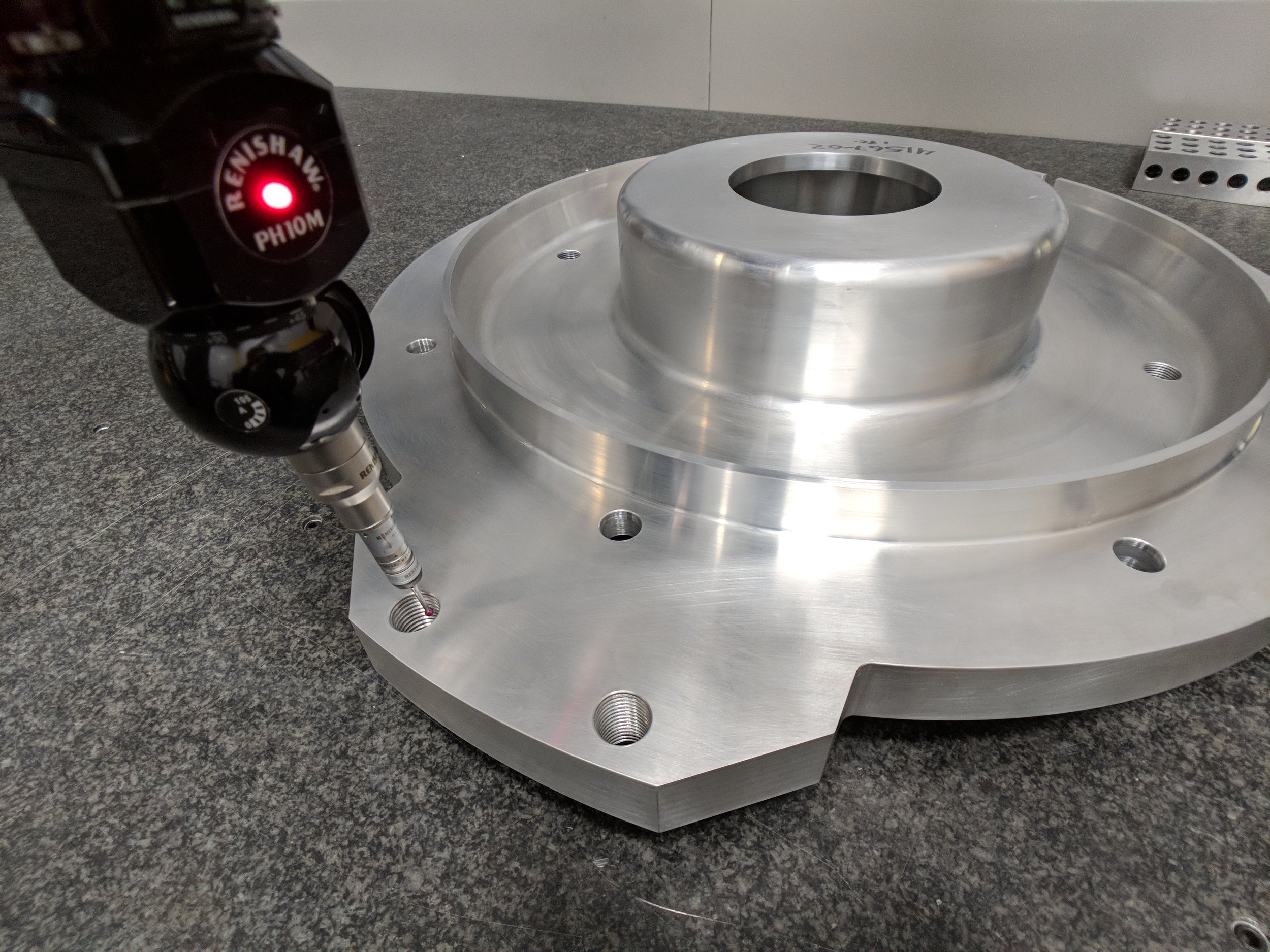

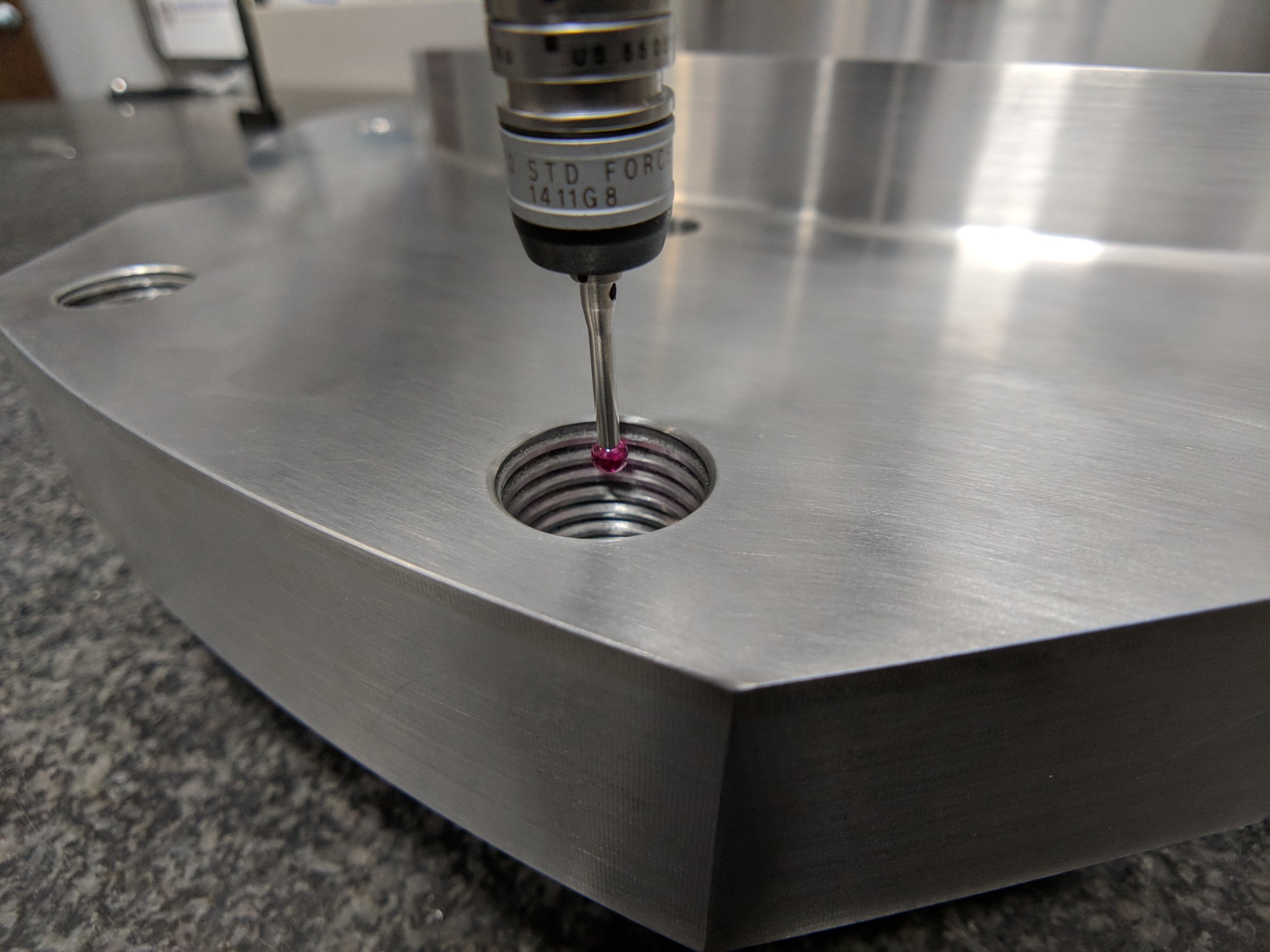

One of our most powerful metrology tools we utilize is a Coordinate Measuring Machine, or CMM. Our large volume CMM allows us to take discrete points on the surface of an object in three dimensions, and then use those points to generate precise and accurate measurements. The benefit of a CMM is the elimination of human error by automating the inspection process through the use of Computer Numerically Controlled (CNC) G-code. We use a powerful inspection software that allows us to program a range of functions in order to better inspect your part. Our dedicated CMM lab in our Houston office is equipped with a multitude of CMM styli that vary in both size and function, which allows us to take the most efficient, accurate, and precise measurements.

Our CMM Part Inspection services can be used for first-article inspection, third-party inspection, quality-assurance, and quality-control services. We provide comprehensive reports that detail whether requirements are met, and our team’s knowledge of Geometric Dimensioning and Tolerancing (GD&T) allows us to provide this information in a clear and concise manner.

Whether the part is large or small, we can accurately inspect components with the tightest of tolerances!